| Section 1 : Introduction to PCB designing concepts |

| a. |

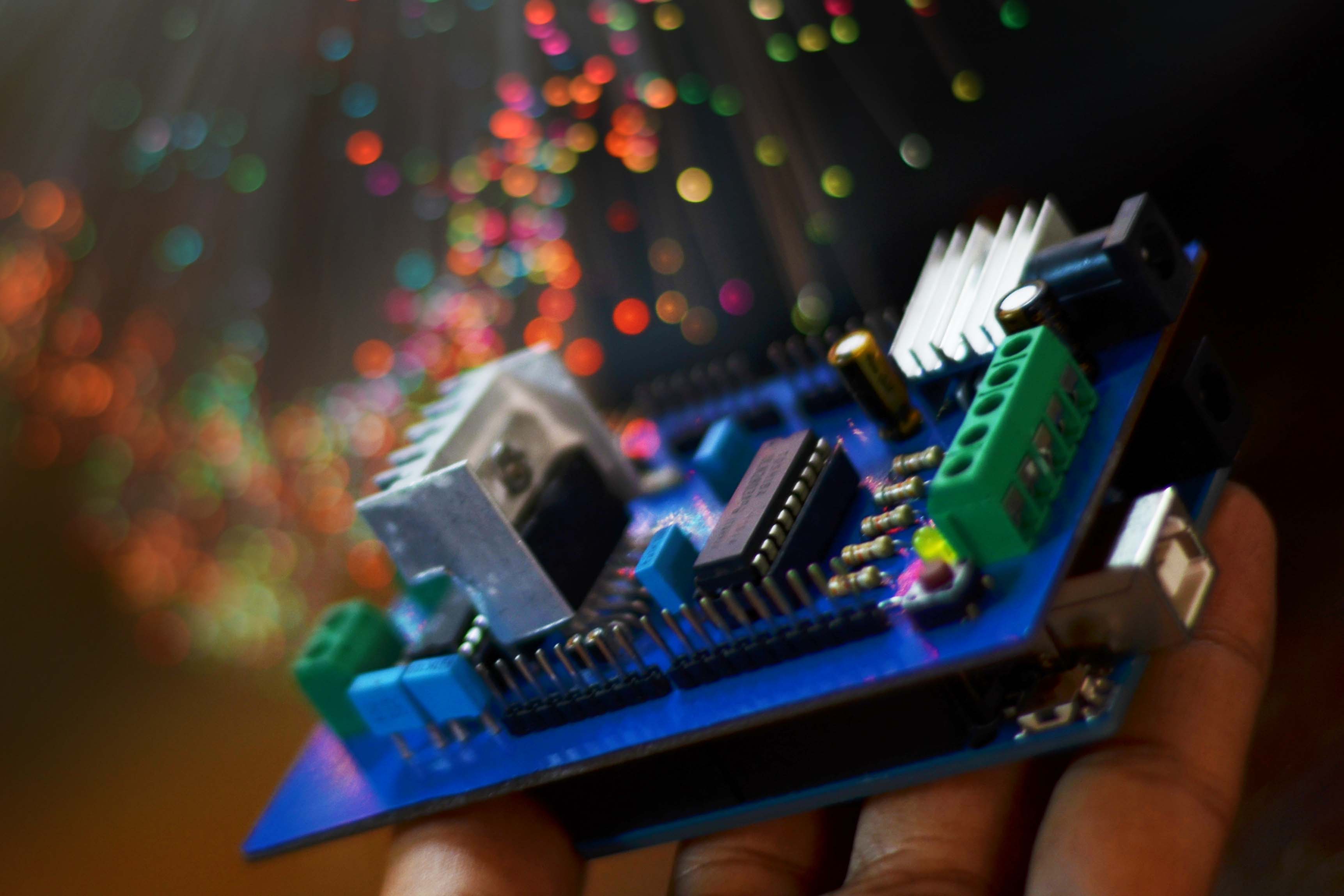

Introduction and brief history |

| |

I. |

What is PCB |

|

|

| |

II. |

Difference between PWB and PCB |

|

|

| |

III. |

Types of PCBs |

|

|

| |

IV. |

Single Sided (Single Layer) |

|

|

| |

V. |

Multi-Layer (Double Layer) |

|

|

| |

VI. |

PCB Materials |

|

|

| b. |

Trends in PCB designing |

| |

I. |

Older PCB Method |

|

|

| |

II. |

PCB Designing Using Graph Paper |

|

|

| |

III. |

Making a hand drawn PCB |

|

|

| |

IV. |

Using Computer for EDA |

|

|

| c. |

Introduction to electronic design automation(EAD) |

| |

I. |

Brief History of EDA |

|

|

| |

II. |

Latest Trends in Market |

|

|

| |

III. |

How it helps and Why it requires |

|

|

| |

IV. |

Different EDA tools |

|

|

| |

V. |

Introduction to SPICE and PSPICE Environment |

|

|

| |

VI. |

Introduction and Woriking of PROTEUS |

|

|

| Section 2 : Component introduction and their categories |

| a. |

Types of components |

| |

I. |

Active Components |

|

|

| |

II. |

Diode |

|

|

| |

III. |

Transistor |

|

|

| |

IV. |

MOSFET |

|

|

| |

V. |

LED |

|

|

| b. |

Component package types |

| |

I. |

Through Hole Packages |

|

|

| |

II. |

Axial lead |

|

|

| |

III. |

Radial Lead |

|

|

| |

IV. |

Single Inline Package(SIP) |

|

|

| |

V. |

Dual Inline Package(DIP) |

|

|

| |

VI. |

Transistor Outline(TO) |

|

|

| |

VII. |

Pin Grid Array(PGA) |

|

|

| |

VIII. |

Through Hole Packages |

|

|

| |

IX. |

Metal Electrode Face(MELF) |

|

|

| |

X |

Leadless Chip Carrier(LCC) |

|

|

| |

XI. |

Small Outline Integrated Circuit(SOIC) |

|

|

| |

XII. |

Quad Flat Pack(QPF) and Thin QFP (TQFP) |

|

|

| |

XIII. |

Ball Grid Array(BGA) |

|

|

| |

XIV. |

Plastic Leaded Chip Carrier(PLCC) |

|

|

| |

XV. |

Inductor |

|

|

| |

XVI. |

Transformer |

|

|

| |

XV. |

Speaker/Buzzer |

|

|

| Section 3 : Introduction to development tools |

| a. |

Introduction of PROTUEUS ISIS software for schematic entry |

| |

I. |

Brief Introduction of various simulators |

|

|

| |

II. |

Description to Proteus ISIS simulator tool |

|

|

| |

III. |

Hands on practice on available library of components |

|

|

| |

IV. |

Working through wiring and schematic designing |

|

|

| |

V. |

Making New Component Symbols |

|

|

| b. |

Introduction of PROTUEUS ARES software for PCB designing |

| |

I. |

Connecting the schematic From ISIS to ARES for Netlising |

|

|

| |

II. |

Selecting the Components Footprints as per design |

|

|

| |

III. |

Picking and placing the Component |

|

|

| |

IV. |

Making New Footprints |

|

|

| |

V. |

Assigning Footprint to components |

|

|

| Section 4 : Detailed description and practicals of PCB designing |

| a. |

PCB Designing Flowchart |

| |

I. |

Schematic Entry |

|

|

| |

II. |

Netlisting |

|

|

| |

III. |

PCB Layout Designing |

|

|

| |

IV. |

Prototype Designing |

|

|

| |

V. |

Design Rule Check(DRC) |

|

|

| |

VI. |

Design For Manufacturing(DFM) |

|

|

| |

VII. |

PCB Making |

|

|

| |

VIII. |

Printing |

|

|

| |

IX. |

Etching |

|

|

| |

X. |

Drilling |

|

|

| |

XI. |

Assembly of components |

|

|

| b. |

Description of PCB Layers |

| |

I. |

Electrical Layers |

|

|

| |

II. |

Top Layer |

|

|

| |

III. |

Mid Layer |

|

|

| |

IV. |

Bottom Layer |

|

|

| |

V. |

Mechanical Layers |

|

|

| |

VI. |

Board Outlines and Cutouts |

|

|

| |

VII. |

Drill Details |

|

|

| |

VIII. |

Documentation Layers |

|

|

| |

IX. |

Components Outlines |

|

|

| |

X. |

Reference Designation |

|

|

| |

XI. |

Text |

|

|

| c. |

Keywords & their description |

| |

I. |

Footprint |

|

|

| |

II. |

Pad stacks |

|

|

| |

III. |

Vias |

|

|

| |

IV. |

Tracks |

|

|

| |

V. |

Color of Layers |

|

|

| |

VI. |

PCB Track Size Calculation Formula |

|

|

| d. |

PCB materials |

| |

I. |

Standard FR-4 Epoxy Glass |

|

|

| |

II. |

Multifuctional FR-4 |

|

|

| |

III. |

Tetra Functional FR-4 |

|

|

| |

IV. |

NelcoN400-6 |

|

|

| |

V. |

GETEK |

|

|

| |

VI. |

BT Epoxy Glass |

|

|

| |

VII. |

Cyanate Aster |

|

|

| |

VIII. |

Plyimide Glass |

|

|

| |

IX. |

Teflon |

|

|

| e. |

Rules for track |

| |

I. |

Track Length |

|

|

| |

II. |

Track Angle |

|

|

| |

III. |

Track Joints |

|

|

| |

IV. |

Track Size |

|

|

| f. |

Study of IPC Standards |

| |

I. |

IPC Standard For Schematic Design |

|

|

| |

II. |

IPC Standard For PCB Designing |

|

|

| |

III. |

IPC Standard For PCB Meterials |

|

|

| |

IV. |

IPC Standard For Documentation and PCB Fabrication |

|

|

| Section 5 : Lab practice and designing concepts |

| a. |

Starting the PCB designing |

| |

I. |

Understanding the schematic Entry |

|

|

| |

II. |

Creating Library & Components |

|

|

| |

III. |

Drawing a Schematic |

|

|

| |

IV. |

Flat Design / hierarchical Design |

|

|

| |

V. |

Setting up Environment for PCB |

|

|

| |

VI. |

Design a Board |

|

|

| b. |

Autorouting |

| |

I. |

Introduction to Autorouting |

|

|

| |

II. |

Setting up Rules |

|

|

| |

III. |

Defining Contraints |

|

|

| |

IV. |

Autorouter Setup |

|

|

| c. |

PCB design practice |

| |

I. |

PCB Designing of Basic and Analog Electronic Circuits |

|

|

| |

II. |

PCB Designing of Power Supplies |

|

|

| |

III. |

PCB Designing of Different Sensor modules |

|

|

| |

IV. |

PCB Designing of Electronics Projects |

|

|

| |

V. |

PCB Designing of Embedded Projects |

|

|

| d. |

Post designing & PCB fabrication process |

| |

I. |

Printing the Design |

|

|

| |

II. |

Eaching |

|

|

| |

III. |

Drilling |

|

|

| |

IV. |

Interconnecting and Packaging electronic Circuits (IPC) Standards

|

|

|

| |

V. |

Gerber Generation |

|

|

| |

VI. |

Soldering and Desoldering |

|

|

| |

VII. |

Component Mounting |

|

|

| |

VIII. |

PCB and Hardware Testing |

|

|

| e. |

Project work |

| |

I. |

Making the schematic of Acedemic and Industrial projects |

|

|

| |

II. |

PCB Designing of these projects |

|

|

| |

III. |

Soldering and Desoldering of componets as per Design |

|

|

| |

IV. |

Testing and Troubleshoting Methods |

|

|

| Section 6 : Project work and documentation |

| a. |

Project work and documentation |

| |

I. |

Description of Project Development Process |

|

|

| |

II. |

Project Discusion & Allotment |

|

|

| |

III. |

Synopsis Making & Submission |

|

|

| |

IV. |

Practice of De-Soldering & Soldering |

|

|

| |

V. |

Introduction to Hardware Techniues |

|

|

| |

VI. |

Project Completion |

|

|

| |

VII. |

Detailed Project Report Submission |

|

|

| |

VIII. |

Final Project PPT |

|

|

| |

IX. |

Feedback Submission (Written & Video) |

|

|

| |

X. |

Certification Distribution |

|

|